Loading/ Unloading on Machine Tool

Adopting home-developed unit control system, we realize work-piece automatic loading/ unloading among load/ unload station, machine tools and work-piece stock.

With high automaticity, unmanned production can be realized, including a series of coherent process such as loading, feeding, machining, cleaning and inspecting.

Application at Tire Factory

Use JLRB100 Palletizer to complete tire automatic palletizing.

Adopt two JLRB20 Robots to accomplish automatic transport of tire tread rubber, replacing porters.

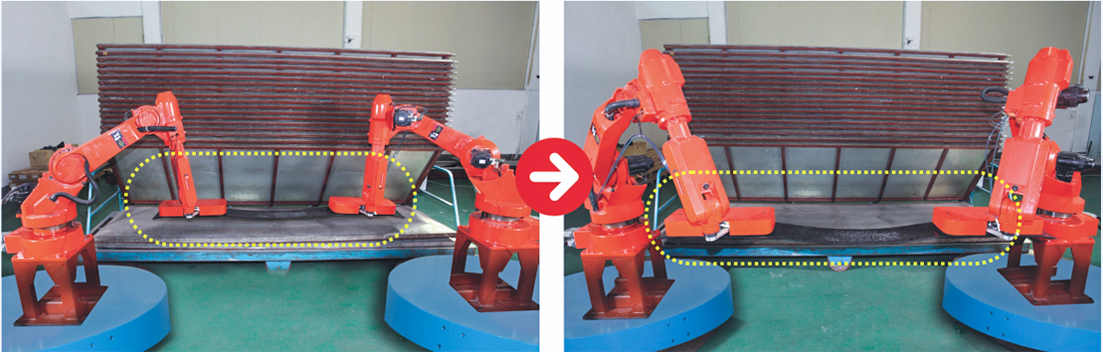

Flexible Production Line

Independent research and development unit control system used to connect many sets of numerical control equipment, composed of flexible automatic production line. With home-developed unit control system, we can connect several numerical control equipment and make up a flexible production line.

Unmanned production can be realized, including a series of coherent process such as loading, feeding, machining, cleaning and inspecting.

Automatic loading, feeding, processing, cleaning, coherent detection, and a series of process, realizing unmanned production.

Welding

Including welding robot welding gun, welding power source, control cabinet, welding machine, wire feeding mechanism, teaching device with robots, under the control of the control system to realize the continuous path control and position control. You can also use of linear interpolation and circular interpolation function welding space composed of line and arc welding. With long-term welding operations, to ensure high productivity and high quality in welding and high stability, etc. Welding robot consists of welding gun, welding power source, control cabinet, welder, wire feeder, teaching device and robot. It completes continuous path control and point-to-point control under control system, and welds the space making up by straight line and arc with linear interpolation and circular interpolation. Welding robots are able to operate for a long time and keep high welding productivity, quality and stability.

Removing burr

Using 3D model, with offline programming and robot linkage technology, we can generate robot program for removing burr to fulfill the removal automatically.